NewWeigh Specials

Since LWA develops and builds the weighers entirely in-house, customisation is always possible. In close consultation with the customer, a suitable solution is sought without compromising the technical feasibility of the project.

NEWWEIGH E14A

An existing weigher was unable to meet the desired capacity, so LWA was asked to replace it. After an initial visit, the dimensions within which the weigher had to be built were recorded. The biggest challenge was the available space, where the linear weigher had to connect to a metal detection feed and was placed above a roller conveyor for filling 15 kg boxes. After an initial visit, the available space is determined and the concept is drawn up. Once the order has been placed, one of the engineers visits to take the final measurements for the weighing machine before it goes into production.

Want to know more about NewWeigh Specials?

De specials van Laurijsen WeegAutomaten hebben een groot aantal voordelen:Laurijsen WeegAutomaten’s specials offer a number of advantages:

- Built specifically to suit the available space

- Software modifications to customer requirements

- Possibility of reusing existing parts

- Very high capacity and accuracy

- Fully stainless steel machine

- Many machine versions

- Customer specification

- Maintenance-free

- Robust and compact construction

- Short changeover time

- Easy to clean

- 35 years of experience

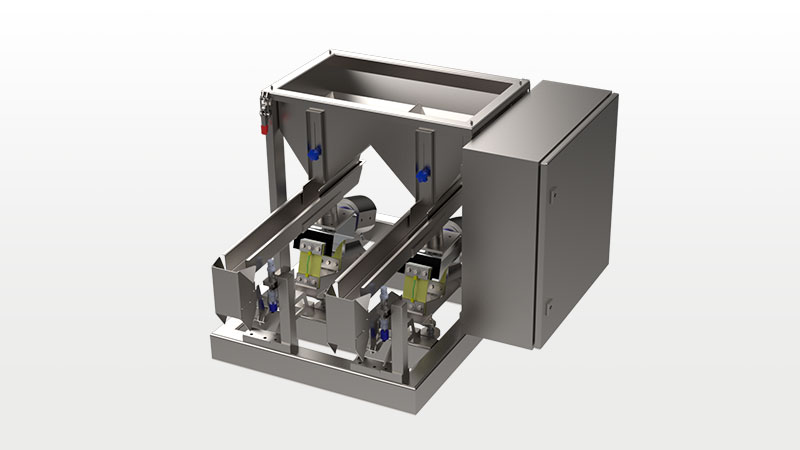

NEWWEIGH E106B

This customer wanted to dose 20 grams of chopped onions onto a tray filled with filet americain. As the available space was limited and the trays were transported at a large distance from each other, it was not possible to use a standard weighing unit.

After extensive testing with different types of onions, a complete tailor-made solution was ultimately developed that fit perfectly into the production line.

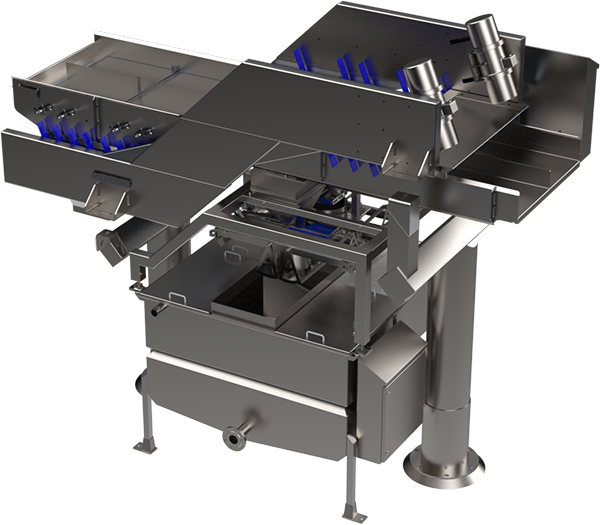

Slivers/nubbins weigher

When cutting potatoes into chips, there is always residual product that is ultimately used to make secondary products (e.g. mashed potatoes). A large Belgian potato processor asked us to weigh these so-called slivers and nubbins so that data could be collected on how much input went to the mashed potato lines.

The challenge in this project lay mainly in the limited installation height available between the shaking chute, which acts as a sieve, and the pump tank into which the slivers and nubbins are dumped. In close consultation with the customer and suppliers of the chute and pump tank, a customised solution was delivered in which the weighed weights are sent to the customer’s ERP system via Modbus communication.